The Role of Safety Light Curtains in Press Brake Operations

The Role of Safety Light Curtains in Press Brake Operations

Press brakes are commonly used in industrial production, but their operation poses various safety risks, including mechanical hazards, electrical dangers, and unintended startups. These risks can severely threaten the safety of operators. To mitigate these risks and ensure personnel safety, safety light curtains have become an efficient and reliable safety solution.

Risk Analysis in Press Brake Operations

Mechanical Hazards: Risks such as crushing, shearing, impact, and flying objects can occur at any time.

Unintended Startups: System malfunctions or operator errors may lead to unintentional machine operation.

Slips and Falls: Uneven or slippery surfaces in the work area can cause accidents.

High-Pressure Fluid Injection: Failures in high-pressure hoses may result in dangerous fluid ejections.

Unintentional Entry into Hazardous Zones: Operators may inadvertently enter dangerous areas during machine operation, especially near dies and press plates.

Key Roles of Safety Light Curtains in Press Brakes

Press Brake Light Curtains

Safety light curtains are non-contact protective devices based on photoelectric technology. They provide real-time monitoring and personnel protection. When a hand or other body part enters the detection area, the machine immediately halts operation, effectively preventing mechanical injuries such as crushing and shearing.

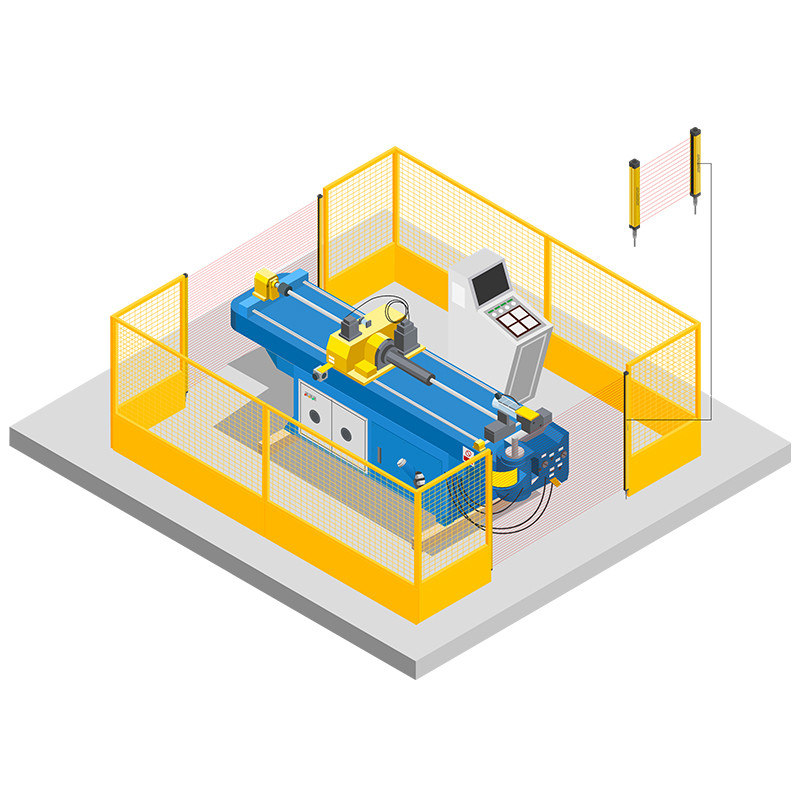

Safety light curtains offer comprehensive protection for press brakes, covering both the front operation area and side hazard zones. In particular, interlocked safety light curtains at the discharge port and side zones prevent unintentional entry into danger areas.

The detection accuracy of the light curtain can be flexibly adjusted according to the operational needs of the bending machine. For example: Detection accuracy within 550 mm of the bending centerline can be less than 40 mm. Detection accuracy beyond 550 mm can be less than 75 mm.

The safety light curtain is integrated with the bending machine's control system. If the light curtain detects an abnormal situation or its beams are interrupted, the equipment will immediately stop to prevent further hazards.

For "V"-shaped dies or other special bending dies, the safety light curtain can be flexibly installed to ensure the detection range aligns with the specific die requirements.

Installation and Optimization Recommendations for Safety Light Curtains

1️⃣ Installation Position

▪️Install light curtains at the front operating area of the press brake to cover the hazardous zone from the discharge port to the die.

▪️Combine side light curtains with fixed protective devices for comprehensive coverage.

2️⃣ Protection Level

▪️Use light curtains compliant with EN ISO 13849-1 and IEC 61496 standards to meet required safety levels.

3️⃣ Integration of Emergency Stop Buttons

▪️Place emergency stop buttons in easily accessible locations and link them with the light curtains for quick response.

4️⃣ Regular Inspection and Maintenance

▪️Operators should regularly inspect the light curtain's performance to ensure its detection sensitivity and interlock stop functions remain reliable during operation.

Recommended Safety Light Curtains

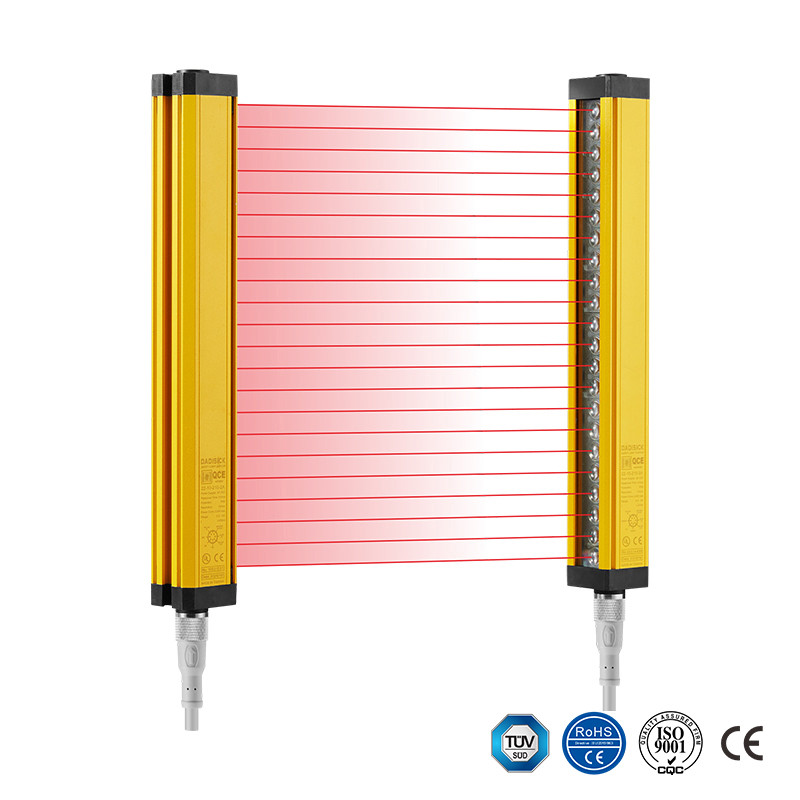

QCE Series Safety light Curtain: General Purpose

Specifications

✅ Comprehensive Protection Functions

▪️ Equipped with polarity protection, short-circuit protection, overload protection, and self-diagnosis capabilities.

▪️ Ensures no erroneous signals are sent to controlled devices in case of sensor failure.

✅ Exceptional Anti-Interference Performance

▪️ Effectively shields 99% of interference signals.

▪️ Exhibits strong resistance to electromagnetic interference, strobe lighting, welding arc light, and ambient light sources.

✅ Ease of Installation and Commissioning

▪️Simple structure design with easy installation and wiring, reducing setup time and cost.

✅ High Reliability Design

▪️Utilizes surface-mount technology (SMT), offering excellent vibration resistance and impact protection.

✅ Fast Response

▪️Response time ≤15ms, ideal for high-speed applications.

✅ Compact Structure Design

▪️Cross-sectional dimensions of 30 mm x 30 mm.

▪️Safety sensors are connected to cables via aviation plugs (M12) for stable and reliable performance.

QT Series Safety light Curtain: The Wide Scanning Range

Specifications

✅ Long-range Through-beam Capability: Maximum through-beam distance reaches up to 45 meters.

✅ Comprehensive Protection Features: Provides polarity, short-circuit, and overload protection with a built-in self-check function. Ensures no incorrect signals are sent to the controlled equipment in case of sensor failure.

✅ Strong Anti-interference Performance: Exceptional resistance to electromagnetic signals, strobe lighting, welding arcs, and ambient light sources, effectively shielding 99% of interference signals.

✅ Robust Design: Adopts surface-mount technology for superior vibration resistance.

✅ Compact Dimensions: Cross-sectional dimensions of 35 mm × 51 mm, connectable to cables via an M12 aviation connector.

✅ Multiple Output Modes: Supports switching output and relay passive output.

✅ Fast Response: Response time ≤15 ms.

✅ Compliance with International Standards:

▪️ Meets IEC 61496-1/2 international safety standards, certified by TÜV and UL.

▪️ Complies with EN 13849-1:2015 (Cat4 PLe) and EN 61496-3:2019 TYPE4.

▪️ Adheres to GB/T 19001-2016 / ISO 9001:2015 management system certification requirements.