The Key to Ensuring Laser Marking Quality — DADISICK Laser Displacement Sensors

The Key to Ensuring Laser Marking Quality — DADISICK Laser Displacement Sensors

Challenge:

Laser marking technology is a critical application in the field of laser processing, widely used for marking and engraving patterns on various materials such as metal and plastic. However, the quality of laser marking is often affected by height instability during the printing process. Any change in the distance between the laser emitter and the marking surface can disrupt precise control of laser intensity, directly impacting the consistency and clarity of the marking results.

Solution:

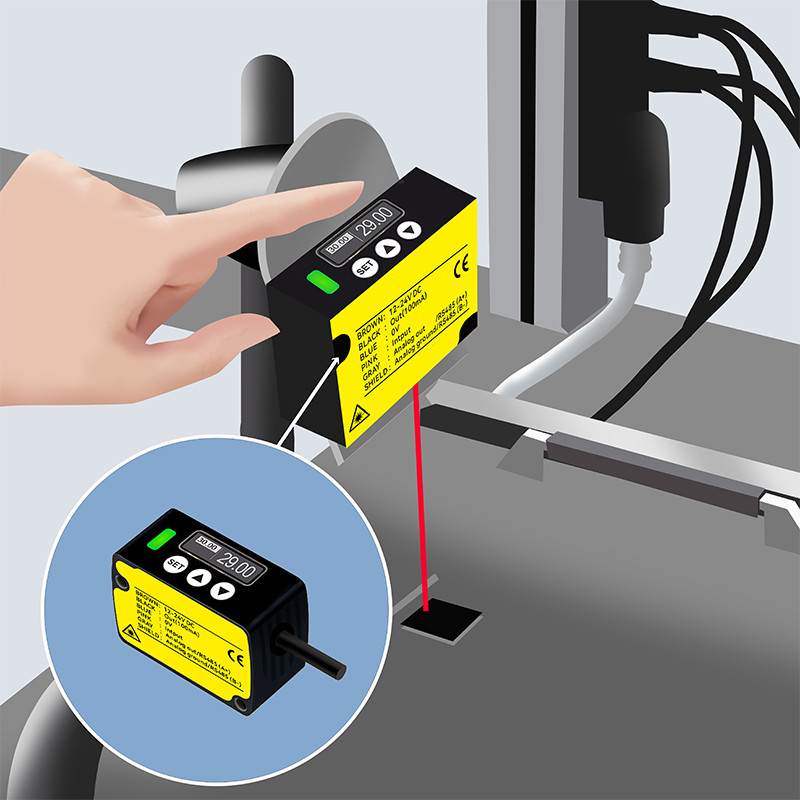

The DADISICK laser displacement sensor offers a perfect solution to this challenge with its exceptional performance. By continuously monitoring height variations at the marking position, the sensor provides real-time feedback on positional data and helps adjust laser intensity. This ensures optimal results for every marking process, maintaining consistency and delivering high-quality markings.

Core Advantages of the GFL-Z Series Laser Displacement Sensors

✅ Micron-Level Measurement Precision

DADISICK laser displacement sensors achieve up to 10 μm accuracy, enabling precise detection of height variations even in high-speed production lines. This ensures reliable data support for laser marking equipment and other demanding applications.

✅ Versatile Communication Interfaces

The sensors support multiple communication options, such as switching output + analog output and switching output + RS485, allowing seamless integration with various automation systems and compatibility with diverse production environments and equipment needs.

✅ Compact and Easy to Integrate

With dimensions of 30 mm × 45.9 mm × 21 mm, the compact design allows the sensor to be easily deployed in limited installation spaces. This not only enhances production line layout flexibility but also reduces costs and time associated with equipment modifications.