Protecting Machines and Personnel in ESD-Sensitive Environments

Protecting Machines and Personnel in ESD-Sensitive Environments

Challenges in ESD-Sensitive Environments

1. The Impact of ESD

On Machinery: Static discharge can damage sensitive circuits in production equipment, leading to operational failures.

On Personnel: ESD can cause discomfort or injuries and increase the likelihood of accidents, especially in environments with conductive materials.

On Productivity: ESD-induced malfunctions result in downtime and increased maintenance costs.

2. Conventional Safeguarding Limitations

Mechanical barriers: While effective in traditional settings, these can accumulate and transfer static, exacerbating ESD issues.

Human error: Operators may bypass safeguards, especially when they are perceived as inconvenient, increasing safety risks.

Why Use Safety Light Curtains in ESD-Sensitive Environments?

Non-Contact Protection

Safety light curtains create an invisible barrier using infrared beams. They eliminate physical contact, reducing the risk of static accumulation that occurs with mechanical guards.

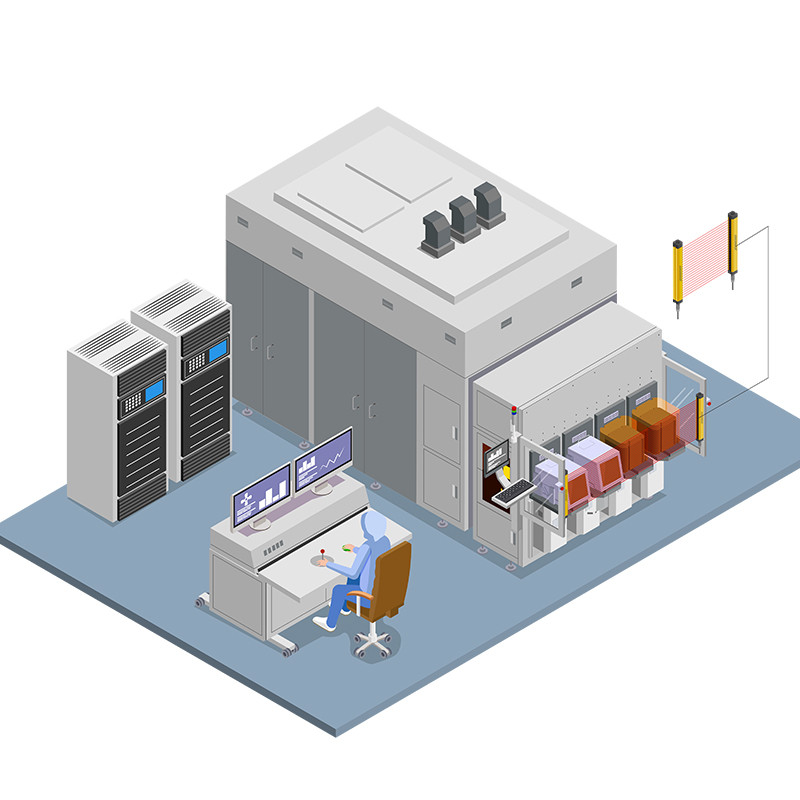

Applications of Safety Light Curtains in ESD Environments

1. Semiconductor Manufacturing

Protect operators working near wafer handlers, lithography systems, or test equipment.

Prevent accidental contact with fragile components while maintaining a static-free environment.

2. PCB Assembly Lines

Safeguard pick-and-place machines or soldering stations where static-sensitive parts are handled.

3. Precision Equipment Maintenance

Provide a safe working zone for personnel during equipment diagnostics or adjustments.

Recommended

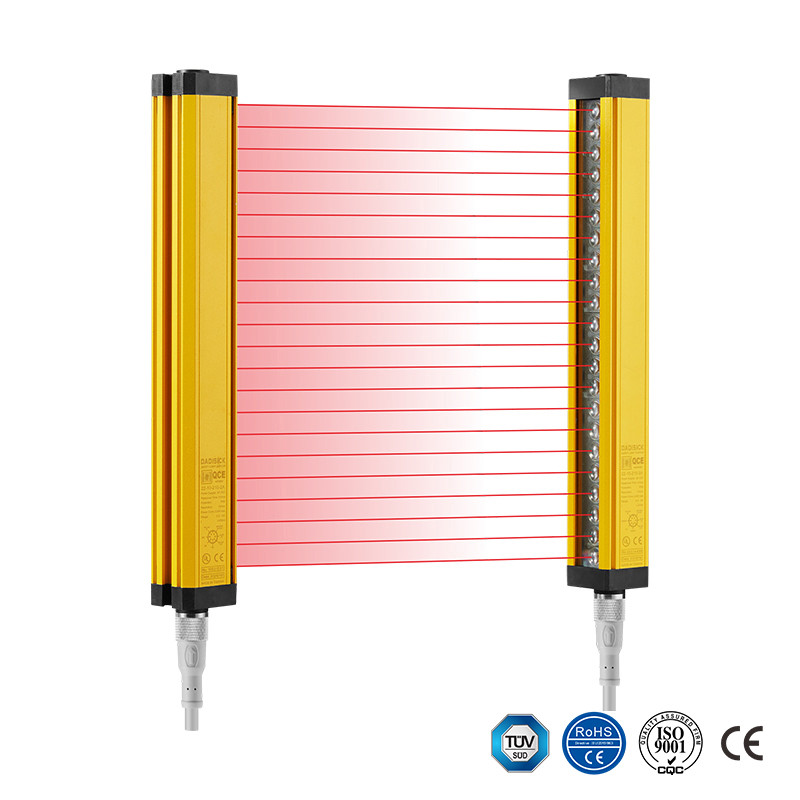

Features of QCE Series Safety Light Curtains

✅ Comprehensive Protection Functions

▪️ Equipped with polarity protection, short-circuit protection, overload protection, and self-diagnosis capabilities.

▪️ Ensures no erroneous signals are sent to controlled devices in case of sensor failure.

✅ Exceptional Anti-Interference Performance

▪️ Effectively shields 99% of interference signals.

▪️ Exhibits strong resistance to electromagnetic interference, strobe lighting, welding arc light, and ambient light sources.

✅ Ease of Installation and Commissioning

▪️Simple structure design with easy installation and wiring, reducing setup time and cost.

✅ High Reliability Design

▪️Utilizes surface-mount technology (SMT), offering excellent vibration resistance and impact protection.

✅ Fast Response

▪️Response time ≤15ms, ideal for high-speed applications.

✅ Compact Structure Design

▪️Cross-sectional dimensions of 30 mm x 30 mm.

▪️Safety sensors are connected to cables via aviation plugs (M12) for stable and reliable performance.

Specifications

Model Description:

QCE12/10-110 or QCE12-10-110

QCE = Series

12 = Number of Light Beams

10 = Light Beam Spacing (mm)

110 = Protective Height (mm)

Through-Beam Safety Light Curtain | ||||

|

Light Beam Spacing

|

10 mm

|

20 mm |

30 mm

|

40 mm

|

|

Detection Accuracy

|

18 mm

|

28 mm |

38 mm

|

48 mm

|

|

Number of Light Beams

|

12, 14, 16...70

|

6, 8, 10...72 |

4, 6, 8...72

|

4, 6, 8...72

|

|

Protective Height (mm)

|

(Number of Light Beams - 1) × 10

|

(Number of Light Beams - 1) × 20 |

(Number of Light Beams - 1) × 30

|

(Number of Light Beams - 1) × 40

|

Detection Distance | A: 0.3 m - 3 m; B: 0.3 m - 6 m | |||

Response Time | ≤15 ms | |||

Anti-Light Interference | 10000 lux (Incident Angle 5°) | |||

Dimensions (mm) | 30 × 30 × L (L is the Length of Emitter/Receiver) | |||

IP Rating | IP65 | |||