Double Sheet Detection of Solar Wafers in Photovoltaic Chip Production Using Ultrasonic Sensors

Double Sheet Detection of Solar Wafers in Photovoltaic Chip Production Using Ultrasonic Sensors

Solution

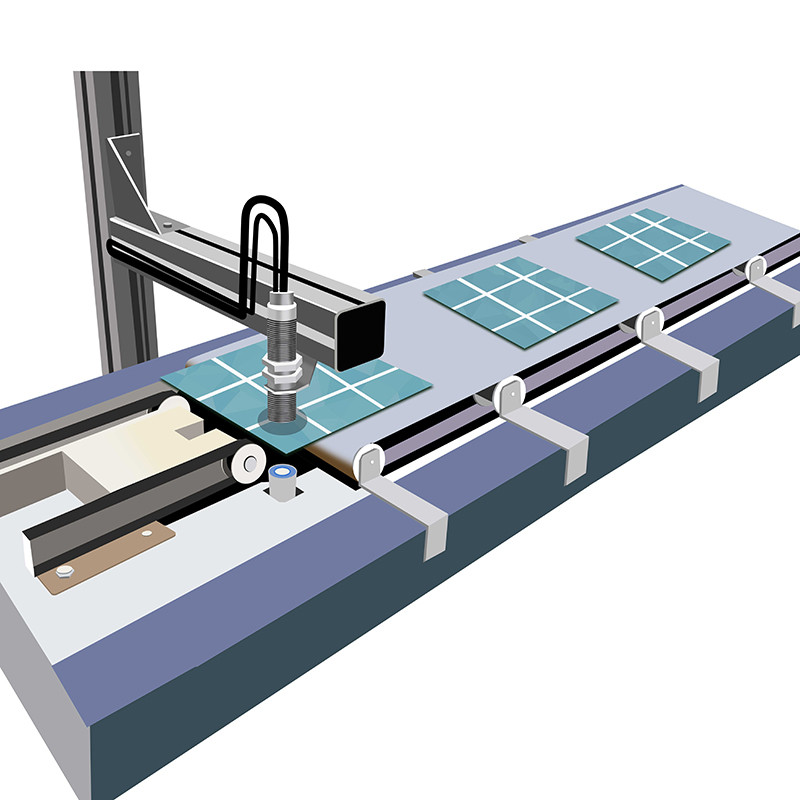

In photovoltaic chip production, solar wafers are both thin and relatively light, making them prone to sliding during the cleaning process. To prevent the breakage or damage of other wafers during subsequent processes (such as handling), stacked wafers must be quickly detected.

The CSDA Series Ultrasonic Double Sheet Sensor can distinguish between single sheets, double sheets, and air, and easily recognize various materials such as paper, films, silicon wafers, adhesive tapes, lithium battery sheets, and PCBs, thereby promptly reporting any errors in positioning to ensure a smooth production process.

Ultrasonic Sensors

CSDA Series Ultrasonic Double Sheet Sensor

▪️Small Blind Zone: The detection range for M12, M18, and M30 models is 20-40 mm, 20-60 mm, and 20-100 mm, respectively, with a minimal blind zone of just 5 mm, 7 mm, and 7 mm, ensuring high-precision detection.

▪️Multiple Output Options: Offers 3 outputs in either NPN or PNP configurations to suit different system requirements.

▪️Auto-learning Function: Supports automatic learning of single and double sheet detection for various materials, providing flexibility for different applications.

▪️Wide Voltage Range: Operates reliably within a DC voltage range of 10~30V, ensuring long-term stability.

▪️Comprehensive Protection: Features short circuit protection, overload protection, and reverse polarity protection for safe and reliable operation.