Application Solutions of Ultrasonic Sensors in PCB Production

Application Solutions of Ultrasonic Sensors in PCB Production

Ultrasonic Technology

Ultrasonic sensors achieve position detection and distance measurement by emitting and receiving ultrasonic waves. The emitter generates ultrasonic pulses that travel through the air and reflect off objects (e.g., PCBs) with different acoustic properties. These reflected waves are captured by the sensor’s receiver and converted into electrical signals. The built-in high-precision timing module calculates the round-trip time of the sound waves. Using the formula:

Distance = Speed × Time ÷ 2, the sensor precisely calculates the distance to the PCB, providing reliable measurement data for various applications.

This non-contact detection technology ensures high accuracy and prevents physical damage such as scratches or wear on PCBs, establishing a solid foundation for precise positioning and quality inspection in PCB production.

Application Scenarios

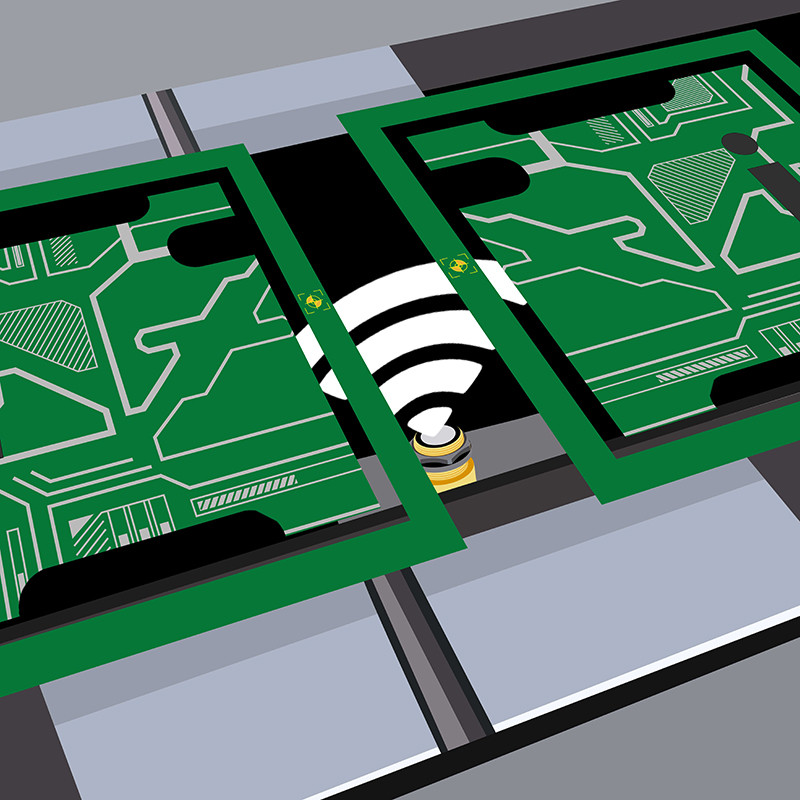

1. Ultrasonic Sensors in Automatic Placement Machines

In automatic placement machines, the precise mounting of components is crucial. Ultrasonic sensors monitor the position of PCBs in real-time and provide accurate coordinate data. With this data, the placement machine's nozzles can align quickly with the mounting points, avoiding errors like misaligned soldering or improper placement. This approach not only improves placement efficiency but also ensures product consistency and reliability.

2. Ultrasonic Sensors in Automated Production Lines

In automated production lines, PCBs must move smoothly along the conveyor. Ultrasonic sensors monitor the PCB’s trajectory in real-time, capturing positional deviations and feeding signals back to the control system. The system then adjusts the PCB’s position promptly, ensuring it moves along the correct path. This closed-loop control mechanism prevents collisions and damage caused by deviation, ensuring uninterrupted production.

3. Ultrasonic Sensors in PCB Inspection Equipment

In quality inspections, ultrasonic sensors can detect internal defects in PCBs. By analyzing the reflective characteristics of ultrasonic waves, the sensors identify issues like short circuits or open circuits and transmit data to the inspection system in real-time. This method is precise and efficient, allowing early-stage detection of defects, reducing rejection rates, and improving final product quality.

Advantages of Ultrasonic Sensors

▪️Non-Contact Detection: Prevents physical damage to PCBs, preserving their surface integrity.

▪️High-Precision Measurement: Resolutions up to sub-millimeter levels meet stringent positioning requirements.

▪️Fast Response: Captures real-time positional changes of PCBs, providing precise feedback to production equipment.

▪️Strong Environmental Adaptability: With temperature compensation, sensors maintain stable performance under various conditions.

Solution – CSB12 Series Ultrasonic Sensors

1. Design Features

The CSB12 series adopts a compact M12 threaded design, with a minimum length of just 50mm, making it ideal for installation in limited spaces. Its small form factor is well-suited for automatic placement machines and inspection equipment, offering easy installation and maintenance.

2. Output Options and Detection Performance

▪️Multiple Output Options: Supports switching, analog, RS485, and IO-Link outputs to meet diverse system requirements.

▪️Flexible Detection Ranges: Offers two measurement ranges of 20-120mm and 20-200mm to suit specific needs.

▪️High Resolution: Accuracy up to 0.1mm, capable of detecting subtle position changes in PCBs.

▪️Temperature Compensation: Automatically adjusts detection accuracy to ensure stable operation in various temperature environments.

3. Application Effectiveness

Case studies demonstrate that the CSB12 series significantly improves the positioning accuracy and quality inspection efficiency of PCBs while reducing production line failure rates and operating costs.